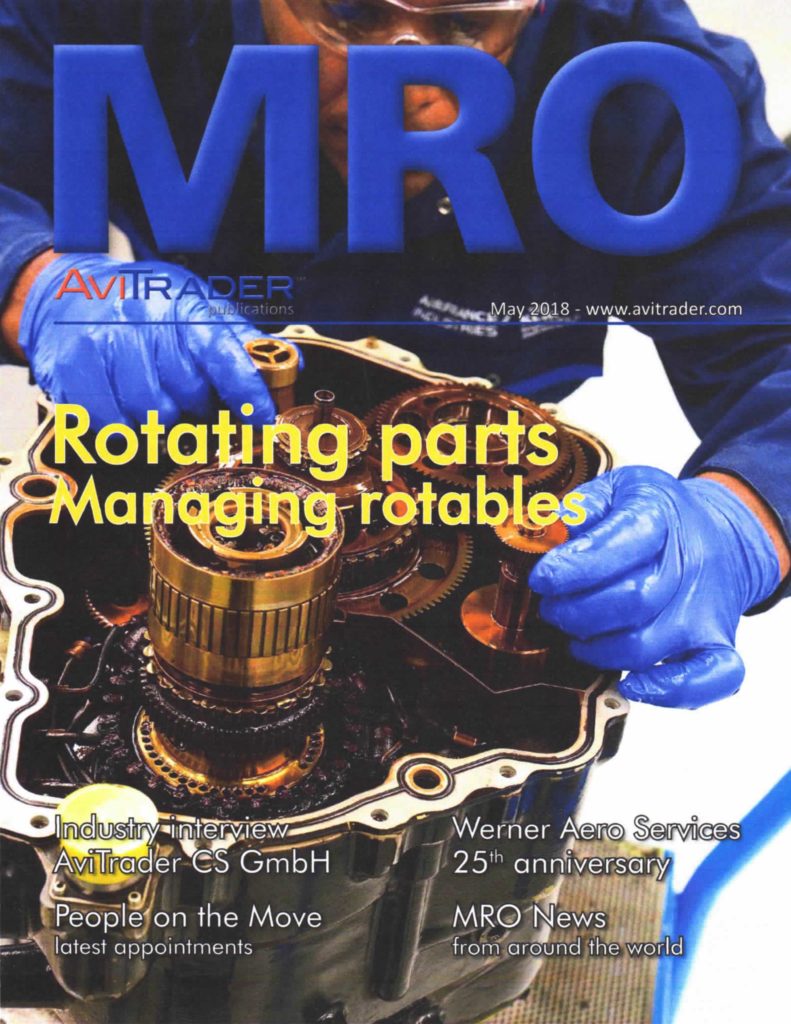

A good rotable inventory system should be able to optimise inventory and lower cost while meeting the target service. Keith Mwanalushi provides an overview of rotable pooling solutions

‘Rotables’ are those components of the aircraft which need to be ‘rotated’ at frequent intervals and air operators will usually keep a stock of such items. Rotables are aircraft parts or components that are serialized and tracked on an airline’s database. It is also a part that can be rebuilt or overhauled (in-house or by a vendor) and put back in stock to use again. Rotables are basically the opposite of “expendable” (throw-away) parts.

By signing a rotable support agreement with AAR, Deepak Sharma, SVP of Integrated Solutions – Commercial says operators lower capital costs because they no longer have to invest in multiple parts at multiple locations. “They gain access to AAR’s parts pools at guaranteed service levels. Given AAR’s long history of buying, selling and repairing components, we also have usage data, in addition to any data provided by the customer, we use gains to optimise inventory and lower the costs of carrying rotables.”

A robust system is key to optimising inventory, says Ian Smith, Director of Commercial Strategy at AJW. “It must be clear, intuitive and above all, flexible.” Smith says the data must be configured in a structured and accurate manner, providing strong foundations on which to build inventory holdings. “Regular housekeeping is key and should be part of day-to-day activity as opposed to an occasional project. Once a clear system is in place, decisions about what to carry where, including decisions around obsolescence, become obvious; it is evident what inventory actions are required to allow the business to meet its business targets, including customer service level commitments, whilst balancing costs.”

With increasing demand for an efficient and cost-effective supply chain for rotables, there have been great efforts within the aviation industry to improve rotable inventory systems and overall inventory management. “The use of a proactive and well-organised rotable pooling system allows operators to reduce costs by carrying smaller inventories,” notes Francis Cradock, CEO at Bii.

Demand forecasting and analysis of big data help to improve operational certainty, predict future problems and boost efficiency.

Bii sees that the use of big data has opened the door to new ways of thinking about business processes which allow for greater inventory optimisation and more accurate health monitoring of aircraft parts and equipment.

To read the full article, please click here